Kyle Gerarden, Bostik04.23.15

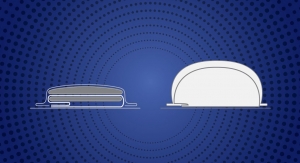

The ongoing movement toward thinner disposable hygiene products means producers must take a completely different approach to core design. As core fluff is decreased or eliminated, core integrity becomes critical. Essential to core integrity are adhesives and the testing of both core integrity and absorption performance.

As with any dynamic system, when the fluff-to-SAP ratio is altered, it can impact the performance of each of the other components. For optimal overall performance, producers and suppliers must look at the core system in a holistic manner.

Testing Core Performance

There is no single, industry standard lab test method to measure core integrity or the stability of the fluff/SAP distribution within the diaper core. Tests being used today range from employing simple tools to complex equipment and from acquiring quantitative to qualitative results. Most of the market focuses on testing core integrity directly by exerting force on the diaper to observe core cracking as a measure of how well the core stays in place within the diaper. The force is generally some type of mechanical dropping, spinning, shaking or swinging after the diaper is insulted with a precise quantity of liquid for a specified length of time.

A more holistic approach goes beyond considering that core integrity is important only when the fluff is wet. It means learning how the core behaves when the wearer is moving because the core needs to remain in one piece, as cracking and shifting before insult could translate into leakage.

Core Integrity Test Methods

The Conditioned Core Cracking Test recognizes the validity of shaking a core to evaluate its integrity, as well as testing, when the core is wet. This test also adds a new element: preconditioning and testing a dry core, or “conditioned core cracking.”

A “crack” is a separation in the core. At some point during the second round of drops, if adhesive is used, the core will separate due to gravity and the weight of the wet fluff, SAP and liquid. As well as being uncomfortable for the user, an additional insult will also not be properly absorbed. Instead, the liquid will creep into the crack that has been created and is likely to leak out of the diaper.

Other test methods include:

Core Cracking: Quantitative test: analyzes diapers, often using a Hardy Integrity Tester (HIT). After insult, the core is dropped until cracking is observed.

Spin/Tumble Testing: Qualitative test: after insult, diaper is placed in a washer, dryer or centrifuge type device, sometimes with tennis balls or other objects inside or outside of the diaper, and observed for cracking after a fixed amount of time.

Core Shaking: Qualitative analysis: after insult, diaper is shaken on a machine until cracking is seen.

Manual Core Shaking: Qualitative analysis: after insult, diaper is shaken by hand until cracking is observed.

Visual Check for Core Bonding: Qualitative analysis: after insult, Topsheet/layer in contact with core is peeled back to observe retention of SAP/fluff. More retention indicates better wet strength.

Wet Peel: Quantitative test to demonstrate effectiveness of adhesive bonds after insult. A tensile tester records average peel strength in a wet environment. Substrates being bonded may be Tissue/Tissue, Tissue/Nonwoven, Nonwoven/ADL, etc.

Actual Use Testing: Creates a complete picture of actual in-use core cracking: cracking is observed in used diapers received from market testing, consumer feedback, etc.

Considerations for Absorption Performance

While core integrity plays a powerful role in absorption performance, good core integrity results don’t automatically equate to good absorption performance. Absorption performance should also be closely evaluated as part of a holistic approach.

To ensure absorption performance, manufacturers should evaluate:

• Acquisition. How fast liquid can be absorbed into the core, sometimes under pressure

• Distribution. How well the entire core is utilized after acquisition

• Rewet. How effective is the core at keeping wetness away from the skin under pressure after initial and multiple insults

• Total Capacity. Measures maximum amount of liquid core will hold

• Wicking. How far can liquid be transported within the core, associated with core density/compaction

Conclusion

As the thin core trend grows and continues to spread across the global market, it’s critical that producers and suppliers adopt a holistic approach in answering the demand. An important part of that holistic approach is understanding the various test methods and applying the ones that test against defined performance goals while reflecting the consumer’s experience in use.

_____________________________________________________________________________________________

Kyle Gerarden is an Applications Specialist and Chemist at the Global Nonwovens business unit of Bostik.

As with any dynamic system, when the fluff-to-SAP ratio is altered, it can impact the performance of each of the other components. For optimal overall performance, producers and suppliers must look at the core system in a holistic manner.

Testing Core Performance

There is no single, industry standard lab test method to measure core integrity or the stability of the fluff/SAP distribution within the diaper core. Tests being used today range from employing simple tools to complex equipment and from acquiring quantitative to qualitative results. Most of the market focuses on testing core integrity directly by exerting force on the diaper to observe core cracking as a measure of how well the core stays in place within the diaper. The force is generally some type of mechanical dropping, spinning, shaking or swinging after the diaper is insulted with a precise quantity of liquid for a specified length of time.

A more holistic approach goes beyond considering that core integrity is important only when the fluff is wet. It means learning how the core behaves when the wearer is moving because the core needs to remain in one piece, as cracking and shifting before insult could translate into leakage.

Core Integrity Test Methods

The Conditioned Core Cracking Test recognizes the validity of shaking a core to evaluate its integrity, as well as testing, when the core is wet. This test also adds a new element: preconditioning and testing a dry core, or “conditioned core cracking.”

A “crack” is a separation in the core. At some point during the second round of drops, if adhesive is used, the core will separate due to gravity and the weight of the wet fluff, SAP and liquid. As well as being uncomfortable for the user, an additional insult will also not be properly absorbed. Instead, the liquid will creep into the crack that has been created and is likely to leak out of the diaper.

Other test methods include:

Core Cracking: Quantitative test: analyzes diapers, often using a Hardy Integrity Tester (HIT). After insult, the core is dropped until cracking is observed.

Spin/Tumble Testing: Qualitative test: after insult, diaper is placed in a washer, dryer or centrifuge type device, sometimes with tennis balls or other objects inside or outside of the diaper, and observed for cracking after a fixed amount of time.

Core Shaking: Qualitative analysis: after insult, diaper is shaken on a machine until cracking is seen.

Manual Core Shaking: Qualitative analysis: after insult, diaper is shaken by hand until cracking is observed.

Visual Check for Core Bonding: Qualitative analysis: after insult, Topsheet/layer in contact with core is peeled back to observe retention of SAP/fluff. More retention indicates better wet strength.

Wet Peel: Quantitative test to demonstrate effectiveness of adhesive bonds after insult. A tensile tester records average peel strength in a wet environment. Substrates being bonded may be Tissue/Tissue, Tissue/Nonwoven, Nonwoven/ADL, etc.

Actual Use Testing: Creates a complete picture of actual in-use core cracking: cracking is observed in used diapers received from market testing, consumer feedback, etc.

Considerations for Absorption Performance

While core integrity plays a powerful role in absorption performance, good core integrity results don’t automatically equate to good absorption performance. Absorption performance should also be closely evaluated as part of a holistic approach.

To ensure absorption performance, manufacturers should evaluate:

• Acquisition. How fast liquid can be absorbed into the core, sometimes under pressure

• Distribution. How well the entire core is utilized after acquisition

• Rewet. How effective is the core at keeping wetness away from the skin under pressure after initial and multiple insults

• Total Capacity. Measures maximum amount of liquid core will hold

• Wicking. How far can liquid be transported within the core, associated with core density/compaction

Conclusion

As the thin core trend grows and continues to spread across the global market, it’s critical that producers and suppliers adopt a holistic approach in answering the demand. An important part of that holistic approach is understanding the various test methods and applying the ones that test against defined performance goals while reflecting the consumer’s experience in use.

_____________________________________________________________________________________________

Kyle Gerarden is an Applications Specialist and Chemist at the Global Nonwovens business unit of Bostik.