David Freund, North American R&D Technical Manager, Bostik Global Nonwovens Business Unit02.25.16

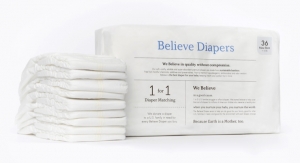

Odor of a disposable hygiene product while in use is, to some degree, to be expected. But odor of the product itself, fresh out of its packaging before use, can be unexpected – and unwelcome. David Freund, the North American R & D Technical Manager of Bostik’s Global Nonwovens Business Unit, recently presented on the challenges of identifying and testing for product odor at the first annual Hygienix conference. Bostik Product Development Chemist Shani Renau-Ferrer spearheaded much of the company’s research on product odor. Her work has proven that identifying and eliminating the source of an odor can be a very arduous process. What makes product odor so complicated?

Science of an Odor

An odor is caused by one or more volatile chemical compounds that we perceive by the sense of smell. The odor signal, or reaction, that is triggered depends on an individual’s sensors and culture. Perception is key to determining the acceptability of anything, especially an odor. Our senses are perception reactors, and they impact the final identification of a stimulus. It only takes a split second for your senses to perceive whether something smells pleasant or unpleasant.

Take, for example, the durian fruit. Native to Southeast Asia, this fruit emits a very, very strong odor that Asians are used to, but tourists can find repulsive. The durian odor – described as a mix of rotten onions and raw sewage - is acceptable in Asia as Asians are used to its strong smell, but it is at first highly offensive to other cultures. Much like the durian fruit, the odor of a disposable hygiene product that is considered to be offensive or unacceptable in one region might be perfectly acceptable in another.

Source of Odor

Identifying the source of an odor is not an easy task. All materials create an overall odor profile and can contribute to product odor. These materials include:

• SAP

• Pulp

• Film

• Elastic

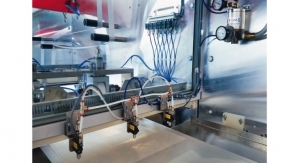

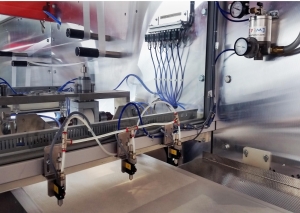

• Adhesive

• Nonwovens

The interaction of these materials results in the final odor by the offsetting and combining of individual material odors, complicating the identity of the source.

Measurement of Odor

There are two types of methods to measure odor: sensory panels and analytical techniques.

Asensory panel is a group of trained individuals who evaluate odor in a standardized way.This is a not an easy task, and there are several challenges that a sensory panel can face. Some major challenges include:

• Repeatability

• Reproducibility

• Cultural/personal bias and sensitivity

• Vocabulary

• The lack of test method standardization in the industry

In order to overcome these challenges, an odor panel must be trained to ensure the results of the panel are not based on personal preference.

Volatiles, on the other hand, are characterized and quantified by analytical techniques. These techniques allow separation and identification of volatile compounds, and can also be coupled with sensory panels to directly link a volatile compound to its odor.

Much like the sensory panel, analytical techniques present some challenges as well. One reason analytical techniques can pose a challenge is because not all volatiles have an odor. Similarly, not all odor-generating compounds can be detected by analytical techniques.

Overcoming Complexity

Finding the root cause of product odor is a very complex process. Sufficient data must be collected to understand the context of the odor, when it occurs, how it is described and by whom. Technical experts must then analyze the data and identify the preferred approach to identify the source of odor and its root cause. After this challenging process is completed, a solutions path (such as odor control or odor masking) can be evaluated and implemented to optimize the product’s odor.

Science of an Odor

An odor is caused by one or more volatile chemical compounds that we perceive by the sense of smell. The odor signal, or reaction, that is triggered depends on an individual’s sensors and culture. Perception is key to determining the acceptability of anything, especially an odor. Our senses are perception reactors, and they impact the final identification of a stimulus. It only takes a split second for your senses to perceive whether something smells pleasant or unpleasant.

Take, for example, the durian fruit. Native to Southeast Asia, this fruit emits a very, very strong odor that Asians are used to, but tourists can find repulsive. The durian odor – described as a mix of rotten onions and raw sewage - is acceptable in Asia as Asians are used to its strong smell, but it is at first highly offensive to other cultures. Much like the durian fruit, the odor of a disposable hygiene product that is considered to be offensive or unacceptable in one region might be perfectly acceptable in another.

Source of Odor

Identifying the source of an odor is not an easy task. All materials create an overall odor profile and can contribute to product odor. These materials include:

• SAP

• Pulp

• Film

• Elastic

• Adhesive

• Nonwovens

The interaction of these materials results in the final odor by the offsetting and combining of individual material odors, complicating the identity of the source.

Measurement of Odor

There are two types of methods to measure odor: sensory panels and analytical techniques.

Asensory panel is a group of trained individuals who evaluate odor in a standardized way.This is a not an easy task, and there are several challenges that a sensory panel can face. Some major challenges include:

• Repeatability

• Reproducibility

• Cultural/personal bias and sensitivity

• Vocabulary

• The lack of test method standardization in the industry

In order to overcome these challenges, an odor panel must be trained to ensure the results of the panel are not based on personal preference.

Volatiles, on the other hand, are characterized and quantified by analytical techniques. These techniques allow separation and identification of volatile compounds, and can also be coupled with sensory panels to directly link a volatile compound to its odor.

Much like the sensory panel, analytical techniques present some challenges as well. One reason analytical techniques can pose a challenge is because not all volatiles have an odor. Similarly, not all odor-generating compounds can be detected by analytical techniques.

Overcoming Complexity

Finding the root cause of product odor is a very complex process. Sufficient data must be collected to understand the context of the odor, when it occurs, how it is described and by whom. Technical experts must then analyze the data and identify the preferred approach to identify the source of odor and its root cause. After this challenging process is completed, a solutions path (such as odor control or odor masking) can be evaluated and implemented to optimize the product’s odor.