One of the studies conducted by EU Commission on top 10 marine litter items found on European beaches highlighted presence of around 8.1% of wet wipes and around 1.4% of feminine hygiene products which are essentially some of the major products made by the nonwoven value chain. As these products are increasingly coming under scanner, there’s a strong need to find sustainable alternatives and that too in a cost-effective way to ensure greater consumer acceptance.

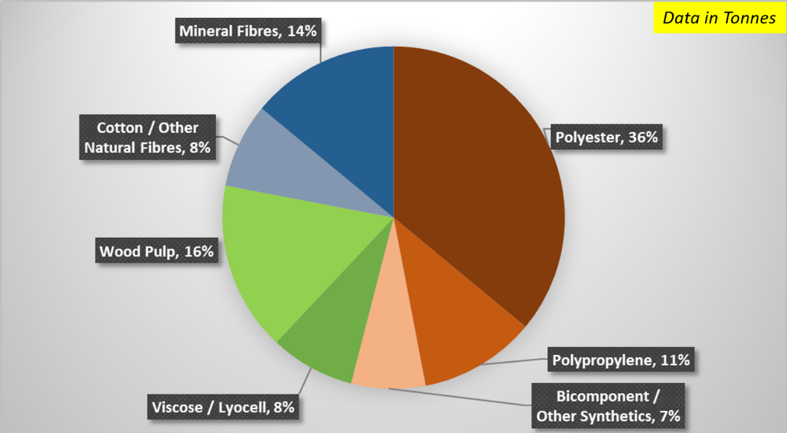

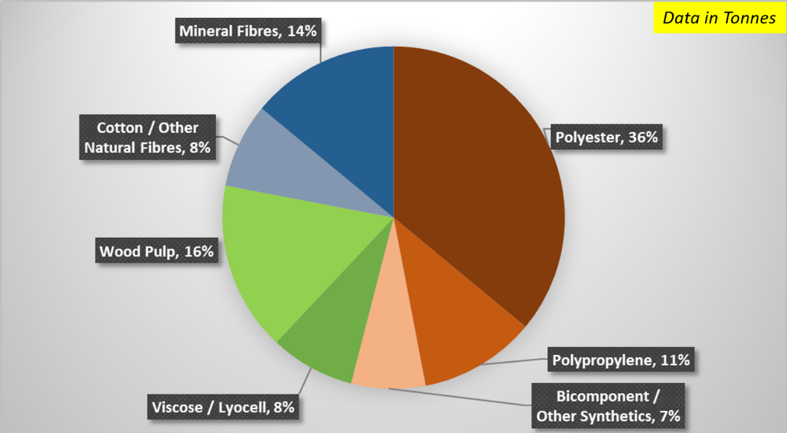

The quest to find sustainable alternatives begins with a sustainable raw material. If we look at the global consumption of all staple fibres used by nonwoven value chain, we could identify the share of plastic based staple fibres used by global nonwoven value chain to around 54% whereas the consumption of next best sustainable alternatives Viscose/Lyocell & Wood Pulp is around 8% & 16% respectively. This clearly indicates that Viscose & Wood Pulp are the solution.

While making the shift to a more sustainable raw material, fibre-technology compatibility is one of the critical factors to consider for the nonwoven value chain. Considering the strict hygiene requirements, it makes it further difficult to use natural fibres whereas regenerated cellulosic fibres like Viscose & Lyocell are engineered for such applications to be able to produce biodegradable nonwovens with desired performance at competitive price.

Looking at different nonwoven process technologies, it’s important for the fibres to be able to process at optimum efficiency and get desired results in the product. This is important to evaluate which non-plastic raw material can become a potential solution under the recent EU SUPd ruling.

Key Nonwoven Technologies & Compatibility of Non-Plastic Raw Material

Options for Wipes / Feminine Hygiene Products

In this regard, Birla PurocelTM has developed a range of sustainable fibre innovations for various nonwoven applications. Birla PurocelTM is a nonwoven fibre brand of Birla Cellulose. At Birla PurocelTM, their philosophy is based on three key pillars – Planet, Innovation & Partnerships. Based on the same philosophy, Birla launched plethora of innovative fibres like Purocel EcoDry, Purocel EcoFlush, Purocel Antimicrobial, Purocel Quat Release (QR) and Purocel Eco to name a few.

|

Sustainability Challenge |

Birla Purocel Offerings |

Description |

|

AHP Plastic Challenge |

Purocel EcoDry

|

Biodegradable and compostable Viscose fiber with engineered hydrophobicity for sustainable and environmentally friendly absorbent hygiene disposable products (AHPs) |

|

Flush-ability Challenge |

Purocel EcoFlush

|

It can be used to make flushable wipes which prevents sewage clogging. The short length fibers provide a fine balance between strength and dispersion |

|

Chemical Challenge in Wet Wipes Formulation |

Purocel Antimicrobial |

Fortified fiber that helps to create nonwovens which restrict microbial growth including viruses and bacteria; and kills them to the extent of 99.9 % (T&C apply) |

|

Plastic Challenge in Disinfecting Wipes |

Purocel Quat Release (QR)

|

Sustainable fibers for effective cleaning and disinfection. These specialty fibers have been infused with a quat release technology which enables easy and quick release of quats during cleaning |

|

Traceability Challenge |

Purocel Eco

|

Eco-enhanced Viscose for a better tomorrow. It can be identified in the end products through a unique molecular tracer which can be traced to its origin |

All these Purocel offerings are just of few of Birla’s many innovative fibres for plethora of nonwoven applications. Birla has invested in state-of-the-art R&D which is enabling them to create these Innovative fibres for a better Planet by closely working with their value chain partners through Partnerships.

Understanding the importance of quick delivery of sustainable innovations to consumers in the form of end product, Birla moved from self-development of fibre to co-creation of the final product - as one of the best ways to fast-track development cycle. Birla’s co-creation approach was used in developing their product Purocel EcoDry which was validated through a consumer research for end product and they worked in collaboration with downstream value chain partners to reach the end product solution which is workable for the value chain and acceptable to brands/consumers.

More information: Rahul.Bansal@adityabirla.com